3 Type of Starter System And Its Functions. Automotive, Technology, Electrical, Starter System,

Technology Automotive - 3 Type of Starter System And Its Functions -

FUNCTION 3 TYPE OF STARTER SYSTEM

1. As the prime Mover, when the engine was first turned on

3 TYPES OF THE STARTER SYSTEM:

1. Planetary Type.

In this type of starter uses three pieces of gear as armature shaft armature as well as the armature drive itself before turning the clutch and pinion gear.

2. Reduction Type.

In this type of starter there are gear-gear that reduces from the armature coil to the gear on the coupling shaft.

3. Conventional Type.

In this type of starter there is only one gear that is pinion gear that will connect to fly wheel gear when drive lever push the gear when the starter spins.

Explanation

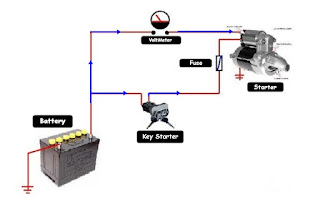

Let's just talk about the main point of the article. To narrow the subject matter about starter system, I will only discuss about conventional type starter system only. like the picture below.

MAIN COMPONENTS AND CONVENTIONAL STARTER TYPE SYSTEM FUNCTIONS

1. SWITCH STARTER

To disconnect and connect the electrical current from the battery

2. SPRING PLUNGER

To restore the plunyer position after pressing and pushing the drive lever

3. PLUNGER

To push and hook the drive lever

4. DRIVE LEVER

To push the clutch and pinion gear to connect to the flywheel gear

5. FRONT CASE

To close the front of the starter

6. STOP COLAR

To limit the movement of the clutch and pinion gear on the shaft

7. PINION GEAR

To play the pinion gear

8. STARTER CLUTCH

To limit the quick rotation of the clutch

9. ARMATURE

To cause a magnetic field in a circular direction

10.COMUTATOR

For the position of the charcoal brush that will drain the electricity to the armature so that it goes round

11.WASHER

To limit and lock the rear axis of the starter

12.FIELD COIL

To cause the magnetic field in a straight and horizontal direction

13.BRUSH HOLDER

For positions of positive and negative brushes

14.BRUSH

To conduct an electric current on the commutator

15.REAR CASE

To close the front starter

16. BOLT

To tie the whole component of the starter system

MAIN COMPONENTS MAIN SYSTEM STARTER CONVENTIONAL TYPES

2. ARMATURE.

Function: To generate a magnetic field in a circular direction.

3. CIRCUITS AND BRUSHES.

Function: as a place of positive and negative brush position and also to conduct electrical current at commutator.

4. SWITCH STARTER.

There are 3 Terminals on the starter switches: 30, 50 and C

and there are also two main coils: Pull in Coil and Hold in Coil.

HOW TO STARTER SYSTEM WORK IN THE CIRCUIT?

Thank you for visiting and reading on our site Technology Automotive. See you later.